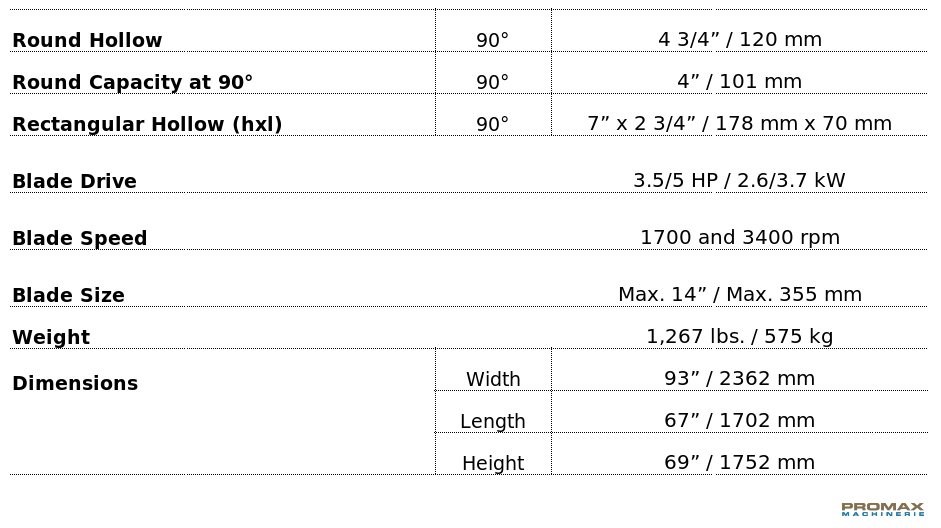

Featuring a 4 3/4″ round hollow capacity at 90°, 2.5/ 3 HP motor, and a 14″ blade, the PNF350-2CNC is the ideal choice for quick, clean, accurate cutting of non-ferrous metals.

![]()

![]()

- Automatic and semi-automatic operation

- Shuttle features automatic multi-indexing up 23” in a single stroke with automatic kerf compensation. Powered by ball screw and stepper motor.

- Pneumatic operating saw head feed with regulating dial for feed rate on control panel

- Robust sawing head can tilt 45° left for compound miter cutting

- Two blade speeds achieve speeds of 1700 or 3400 rpm

- Vises are equipped with moveable aluminum jaws which can be adjusted vertically

- Rotating table mounted on large roller bearing to achieve smooth and precise miter cutting. Features stops at 90° and 45° plus screw locking system to lock head at desired degree.

- Two pneumatic operating vises, capable of sliding in or away from the blade to adjust saw head in mitered position

- 3.5/5 Hp blade drive coupled directly to saw head guarantees high rigidity and precision to obtain high chip removal rates.

- Cutting area enclosed behind protective cover which swings up for loading material

- Ergonomically positioned control panel mounted on an articulating arm, with protected membrane buttons for operation control. Includes emergency stop, set or view machine diagnostics and operations such as saw stroke limits and speed, cutting programs, digital display of programs, blade speed, cycle time along with 40 different machine

diagnostics and warnings. Store up to 99 jobs. - One carbide tipped blade included

![]()

- T2500 chip collector

- Short remnant

- Mist lubrication system

- Roller table & accessories

Our objective is to continuously update our website with accurate information on our products. However, ProMaxMachinerie inc. cannot be held accountable for typographical errors or product formulation changes. For absolute accuracy, please consult the products specification. If you discover any inconsistencies on our website please Contact Us.