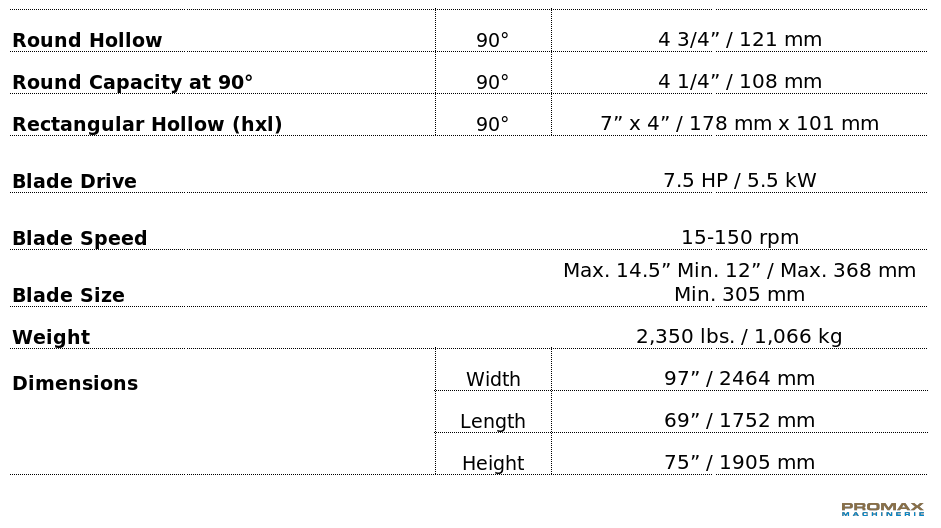

Featuring a 4 3/4″ round hollow capacity at 90°, 7.5 HP motor, and 14 1/2″ blade, the C370-2CNC automatic cold saw is the ideal choice for quick, clean, accurate metal cutting.

![]()

![]()

- Automatic operation with semi-automatic mode

- Shuttle features automatic multi-indexing up to 40” in a single stroke with automatic kerf compensation. Powered by ball screw and stepper motor.

- Shuttle feed carriage designed with side movement to help feed and center deformed parts.

- Variable speed drive from 15 to 150 rpm’s for the best cutting efficiency

- Vertical pneumatic vise

- Extended jaws allow for short remnant

- Heavy duty sawing head movement controlled by electro mechanic cylinder. Head moves on adjustable dual precision linear rails

- Robust sawing head miters 45° left and right, and 60° left

- 7.5 HP blade drive coupled directly to saw head guarantees high rigidity and precision to obtain high chip removal rates.

- Pneumatic operating vise capable of sliding on dovetail to adjust with saw head mitered position

- Enclosed steel base with chip drawer and coolant tank

- Replaceable blade brush

- Ergonomically positioned control panel includes emergency stop, programming console, digital display for machine diagnostics, as well as cutting parameters: blade speed, cut time, and cut quantity. Store up to 32 jobs.

- Flood coolant system with electrical coolant pump

- One blade included

![]()

- Automatic mitering

- CB6001 automatic incline loading table

- Second pneumatic horizontal operating vise

- Automatic chip conveyor

- Mist lubrication system

Our objective is to continuously update our website with accurate information on our products. However, ProMaxMachinerie inc. cannot be held accountable for typographical errors or product formulation changes. For absolute accuracy, please consult the products specification. If you discover any inconsistencies on our website please Contact Us.